Eine Hochleistungs-Nickellegierung, die für Umgebungen mit starker Korrosion verwendet wird

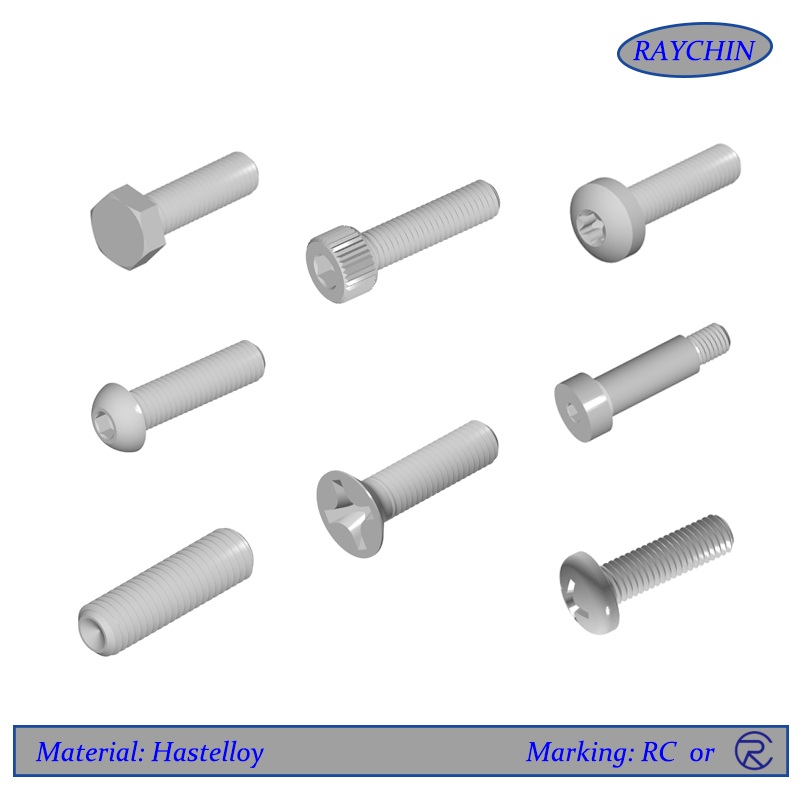

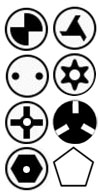

Stile von Hastelloy-Befestigungselementen

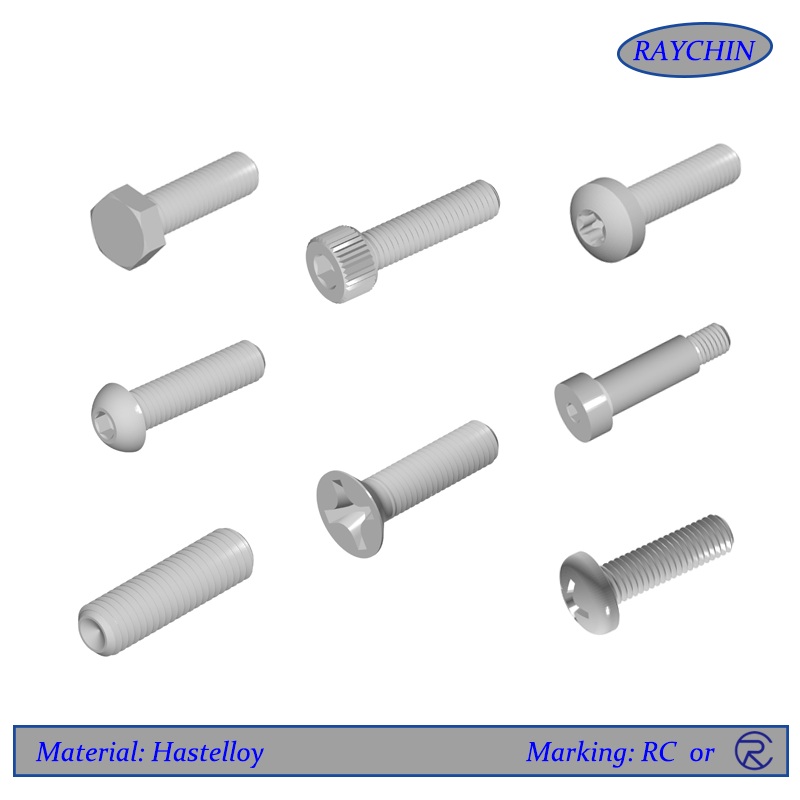

| Hastelloy-Schrauben | 12-Punkt-Schrauben, Halbrundkopfschrauben, Flachkopfschrauben, Sechskantschrauben, Flachkopfschrauben, Sicherheitsschrauben, Stellschrauben, Innensechskantschrauben, Belüftete Schrauben | • DIN 603 / ISO 8677 • DIN 912 / ISO 4762 • DIN 913 / ISO 4026 • DIN 914 / ISO 4027 • DIN 915 / ISO 4028 • DIN 916 / ISO 4029 • DIN 921 • DIN 931 / ISO 4014 • DIN 933 / ISO 4017 • DIN 961 / ISO 8676 | • DIN 965 / ISO 7046 • DIN 966 / ISO 7047 • DIN 7991 / ISO 10642 • DIN 7380 / ISO 7380 • DIN 84 / ISO 1207 • DIN 85 / ISO 1580 • DIN 34822 • DIN 34821 • DIN 7504 / ISO 15480 • DIN 7984 • DIN 963 / ISO 2009 |

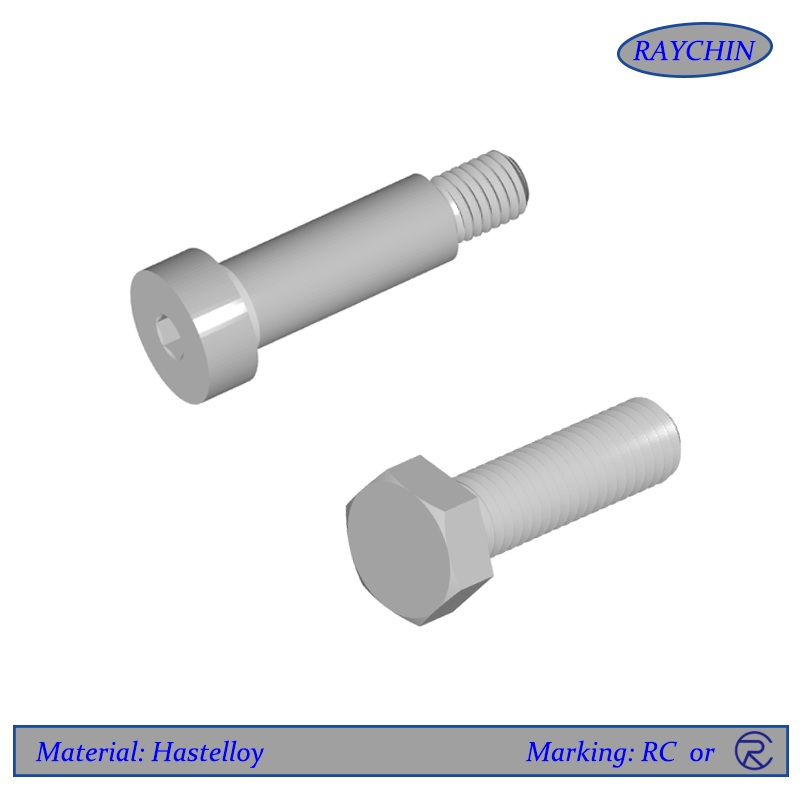

| Hastelloy-Schrauben | Sechskantschrauben, Schulterschrauben, Keilankerschrauben | • DIN 931 • DIN 933 • ISO-4014 • ISO-4017 • ISO-7370 |

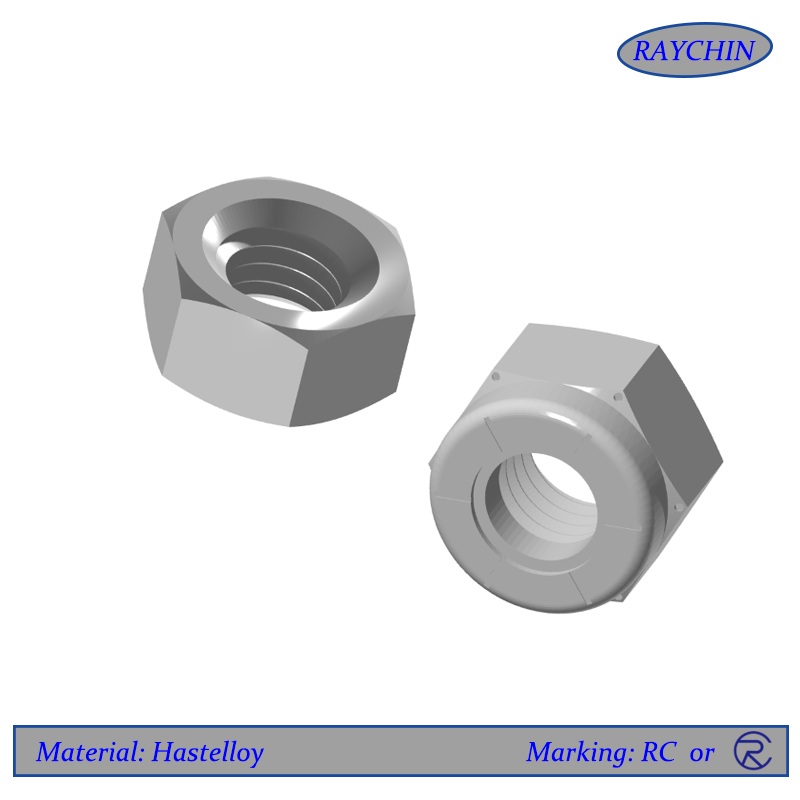

| Hastelloy-Nüsse | Sechskantmuttern, Kontermuttern | • DIN 439 / ISO 4035 • DIN 934 / ISO 4032 • DIN 985 / ISO 7040 • AB 986 • DIN 980 / ISO 7042 / ISO 19513 • DIN 6923 / ISO 4161 |

| Hastelloy Bolzen/Stab | Bolzen, Gewindestangen, Schweißbolzen | • AB 975 • AB 976 |

| Hastelloy-Unterlegscheiben | Flache Unterlegscheiben, Sicherungsscheibe | • DIN 125 / ISO 7089 / ISO 7090 • DIN 126 / ISO 7091 • DIN 127 / ISO 7090 • DIN 9021 / ISO 7093 |

| Hastelloy-Schlauchschellen | Mittelschwere Schlauchschellen |

HASTELLOY C276 (2.4819)

Hastelloy C276 alloy, UNS N10276, 2.4819, is the most widely used and versatile corrosion resistant nickel alloy. Hastelloy fasteners offer very good resistance to strong reducing and moderately oxidizing corrosive acids, as well excellent stress corrosion cracking resistance and resistance to localized attack. Outstanding corrosion resistance to various concentrated, hot acids and reducing environments, C276 fasteners are readily used in hot sulfuric and hydrochloric acid applications. Hastelloy's resistance to sulfuric acid makes it a common choice for protection from hydrogen sulfide (H2S), more commonly known as sour gas.In addition, Hastelloy C276 is one of the few grades resistant to wet chloride gas and chlorine dioxide. The Hastelloy C276 grade also offers excellent mechanical properties at elevated temperatures up to 1500°F / 815°C, making it ideal for hot corrosive environments. Because of these properties, Hastelloy C276 fasteners have resistance to a wide range of acids, chlorides, and strong halides which is why they are often utilized in the chemical processing and the oil & gas industries. The only factor that is critical to point out when dealing with very strong oxidizing environments like nitric acid is that Hastelloy C276 fasteners can be attacked as it has a low chromium content compared to other grades like Hastelloy C22.

HASTELLOY C276 SPEZIFIKATIONEN: N10276, ASTM B574, ASME SB574, Werkstoff 2.4819, ASTM G28-A/B, EN 10204-3.1, ASME B18.2.2, ASTM B619, ASME SB619, ASTM B366, ASME SB366, WPHC276, ASME B16.11 , ASTM B564/ASME SB564, KALTGEZOGEN, WARMBEARBEITET, ASTM B575, ASME SB575, KALTGEWALZT, WARMGEWALZT, ASME B16.9, ASME B16.5, ASTM B462, ASME SB462, ASTM F467 (Muttern), ASTM F468 ( Schrauben, Bolzen, Stehbolzen)

Hastelloy C276 | In | Mo | Kr | Fe | IN | Co | Mn | IN | Und | P | S | C |

Mindest% | BAL | 15.0 | 14.5 | 4.0 | 3.0 | - | - | - | - | - | - | - |

Max% | - | 17.0 | 16.5 | 7.0 | 4.5 | 2,50 | 1.00 | 0,35 | 0,08 | 0/04 | 0,03 | 0,01 |

HASTELLOY B2 (2.4617)

Hastelloy B2-Legierung, UNS N10665, bietet eine hervorragende Beständigkeit gegen Salzsäure bei allen Temperaturen und Konzentrationen, hat jedoch eine schlechte Korrosionsbeständigkeit gegenüber oxidierenden Chemikalien und in Gegenwart von Eisen- oder Kupfersalzen. Darüber hinaus weist Hastelloy B2 eine hervorragende Beständigkeit gegen Lochfraß, Spannungsrisskorrosion und Messerlinien- und Hitzeeinflusszonenangriff auf. B2 enthält jedoch wenig Chrom und sollte NICHT mit oxidierenden Medien in Gegenwart von Salzen verwendet werden. Wie andere Hastelloy-Legierungen können B2-Befestigungselemente im geschweißten Zustand verwendet werden, da sie der Bildung von Korngrenzenkarbidausscheidungen in der Schweißwärmeeinflusszone widerstehen. Es wird empfohlen, B2-Befestigungselemente nicht zwischen 1000 °F und 1600 °F zu verwenden, da sich die Duktilität verringert.

HASTELLOY B2 SPECIFICATIONS: N10665, ASTM B619, Werkstoff 2.4617, ASME SB619, ANNEALED, B/SB619 CLASS I OR II, X-RAY PER ASME SECTION VIII DIVISION 1 UW-51, MERCURY FREE, EN 10204-3.1, ASTM B366, ASME SB366, WPHB2-S, ASME B16.11, ASTM B335, ASME SB335, ASME B16.3, MSS SP-83, ASTM B564/ASME SB564, COLD DRAWN, HOT FINISHED, ASTM B333, ASME SB333, SHEET IS COLD ROLLED, HOT ROLLED, ENIMO-7, AWS A-5.11, ASME SFA-5.11

Hastelloy B2 | Ni | Mo | Fe | Cr | Co | Mn | P | Si | S | C |

Nominal% | BAL | 26-30 | 2 Max | 1 Max | 1 Max | 1 Max | 0.040 | 0.10 | 0.030 Max | 0.020 Max |

HASTELLOY B3 (2.4600)

Hastelloy B3 alloy, UNS N10675, is specifically designed to deal with very aggressive hydrochloric acid (HCl), hyrdrobromic acid (HBr) and sulfuric acids (H2SO4) as well as acetic, formic and phosphoric acids. Hastelloy B3 fasteners deliver the same excellent resistance to hydrochloric acid and other strongly reducing chemicals as other B-alloys (including B2) but with significantly enhanced thermal stability and improved ease of fabrication. However B3 has little chromium, and it should NOT be used with oxidizing media and is not recommended for use in the presence of ferric or cupric salts which can cause rapid corrosion failure.

HASTELLOY B3 SPECIFICATIONS: N10675, ASTM B366, ASME SB366, Werkstoff 2.4600, WPHB3-W, ASME B16.9, ANNEALED, MERCURY FREE, EN 10204-3.1 (W/O X-RAY), ASTM B335, ASME SB335, ASTM B564, ASME SB564, DIMENSIONS PER ASME B16.5, ASTM B462, ASME SB462, ASME B16.5, COLD DRAWN, HOT FINISHED, ASTM B626, ASME SB626, B/SB626 CLASS III, ASTM B333, ASME SB333, COLD ROLLED, HOT ROLLED

Hastelloy B3 | Ni | Mo | Fe | Cr | Co | Mn | P | Si | S | C | W |

Nominal % | 65 Min | 28.5 | 1.5 | 1.5 | 3 Max | 1 Max | 0.040 | 0.10 | 0.030 Max | 0.020 Max | 0.020 Max |

HASTELLOY C22 (2.4602)

Hastelloy C22 alloy, UNS N06022, has better overall corrosion resistance in oxidizing corrosives than C-276 and Inconel 625 alloys due to the higher chromium content. More specifically, C22 fasteners provides better protection when used in certain saturated wet chlorine environments. In addition, its high chromium content provides C22 fasteners much better resistance to oxidizing media that C276. This provides it exceptional resistance to chloride-induced pitting although, in most cases because of its availability, C-276 fasteners are a more cost-effective option. Hastelloy C22 fasteners also offer outstanding resistance to pitting and crevice corrosion, as well as stress corrosion cracking. Use of C22 fasteners should be limited to temperatures below 1250° F. This alloy has limited availability and can be made into fastener in larger diameters only (1/2" and greater in size).

HASTELLOY C22 SPECIFICATIONS: SB 575/B 575, SB 574/B 574, SB 366/B 366 SB 462/B 462, SB 564/B 564 SB 462/B 462, Werkstoff 2.4602, 17744 No. 2.4602 NiCr21Mo14W, NACE MR0175 ISO 15156

Hastelloy C22 | Ni | Mo | Cr | Fe | W | Co | Mn | Cu | V | Si | C |

Nominal % | 56 BAL | 13.0 | 22.0 | 3.0 | 3 Max | 2.5 Max | 0.5 Max | 0.5 Max | 0.35 Max | 0.08 Max | 0.01 Max |

HASTELLOY C2000 (2.4675)

Hastelloy C2000 alloy, UNS N06200, is a corrosion resistant alloy with excellent resistance to uniform corrosion in oxidizing or reducing environments. Hastelloy C2000 fasteners combine the outstanding resistance to oxidizing media of C276 with superior resistance to non-oxidizing environments, making it a unique alloy for protecting chemical process equipment that has a range of conditions. C2000 fasteners are designed to offer greater versatility compared to the other Hastelloy alloys. The addition of copper provides C2000 fasteners enhanced temperature capability in sulfuric acid, hydrofluoric acid, and dilute hydrochloric acid. Due to its high chromium content protects process streams contaminated with ferric ions. In addition, C2000 fasteners have excellent resistance to stress corrosion cracking and superior resistance to localized corrosion as compared to C-276 alloy.

HASTELLOY C2000 SPECIFICATIONS: SB 575/B 575, SB 574/B 574, SB 366/B 366 SB 462/B 462,SB 564/B 564 SB 462/B 462, Werkstoff 2.4675, NACE MR0175 ISO 15156

Hastelloy C2000 | In | Mo | Kr | Fe | Co | Mit | Mn | Al | Und | C |

Nominal % | 59 Kaution | 16.0 | 23.0 | 3 max | 2 max | 1.6 | 0,5 max | 0,5 max | 008 | 0,01 max |

HASTELLOY X (2.4665)

Alloy X, UNS N06002, ist vor allem für seine außergewöhnliche Kombination aus Hochtemperatur-Oxidationsbeständigkeit bis 2000 °C und Hochtemperaturfestigkeit bekannt. Bei hohen Temperaturen stabil, stark und duktil zu sein, sind seine bemerkenswertesten Eigenschaften, die häufig in Gasturbinenkomponenten und Ofenkomponenten verwendet werden.

HASTELLOY X SPEZIFIKATIONEN: AMS 5536, AMS 5754, AMS 5798, ASME SB 435, ASME SB 572, ASME Sect. IX P Nr. 43, ASME Abschnitt IX P Nr. 43, ASME SFA 5.14, ASTM B 435, ASTM B 572, EN 2.4665, GE B50A436, GE B50T83, GE B50TF24, PDS 1038 (X-low), PDS 15102QFC, UNS N06002, Werkstoff 2.4665

Hastelloy X | In | Mo | Kr | Fe | Co | Mit | Mn | Al | Und | IN | Von | P | S | B | C |

Mindest % | BAL | 8.0 | 20.5 | 17.0 | 0,5 | - | - | - | - | 0,2 | - | - | - | - | 0,05 |

Max. % | 10.0 | 23.0 | 20.0 | 2,50 | 0,05 | 1.0 | 0,50 | 1.00 | 1.0 | 0,01 | 0,04 | 0,03 | 0,01 | 0,15 |

Hastelloy-Schrauben

Hastelloy-Schrauben

Hastelloy-Nüsse

Hastelloy Bolzen & Gewindestange

Hastelloy-Unterlegscheiben

MECHANISCHE EIGENSCHAFTEN VON HASTELLOY

C 276 - Zugdaten

Temperatur ℉ | Reißfestigkeit (ksi) | Streckgrenze bei 0,2 % Versatz (ksi) | Dehnung % |

Raumtemperatur. | 107 | 49 | 72 |

400 | 9.5 | 38 | 69 |

600 | 90 | 33 | 67 |

800 | 89 | 33 | 65 |

1000 | 85 | 31 | 63 |

1200 | 80 | 30 | 62 |

1400 | 68 | 27 | 78 |

C22 - Zugfestigkeitsdaten

Temperatur (°F) | Ultimative Zugfestigkeit (ksi) | Streckgrenze bei 0,2 % Versatz (ksi) | Dehnung % |

Raumtemperatur. | 111 | 52 | 70 |

200 | 105 | 45 | 72 |

400 | 96 | 38 | 84 |

600 | 92 | 34 | 73 |

800 | 89 | 31 | 79 |

1000 | 84 | 29 | 80 |

1200 | 80 | 28 | 80 |

1400 | 72 | 29 | 77 |

B2 - Zugfestigkeitsdaten

Temperatur (°F) | Ultimative Zugfestigkeit (ksi) | Streckgrenze bei 0,2 % Versatz (ksi) | Dehnung % |

Raumtemperatur. | 131 | 59 | 61 |

400 | 126 | 52 | 60 |

600 | 122 | 49 | 60 |

800 | 119 | 46 | 61 |

C2000 - Zugfestigkeitsdaten

Temperatur (°F) | Ultimative Zugfestigkeit (ksi) | Streckgrenze bei 0,2 % Versatz (ksi) | Dehnung % |

200 | 105 | 46 | 70 |

400 | 98 | 41 | 69 |

600 | 89 | 35 | 73 |

800 | 88 | 31 | 73 |

1000 | 85 | 31 | 75 |

1200 | 80 | 30 | 71 |

HASTELLOY X - Zugfestigkeitsdaten

Temperatur (°F) | Reißfestigkeit (ksi) | Streckgrenze bei 0,2 % Versatz (ksi) | Dehnung % |

Zimmer | 111 | 55 | 44 |

1000 | 89 | 36 | 49 |

1200 | 84 | 35 | 54 |

1400 | 67 | 34 | 53 |

1600 | 45 | 28 | 59 |

1800 | 26 | 13 | 66 |

2000 | 14 | 6 | 60 |

DRUCK-TEMPERATURWERTE

FÜR LEGIERUNGEN C276 / 625 / 825

Nominelle Bezeichnung | Schmiedestücke | Gussteile | Platten | ||||

54Ni 16Mo 15Cr | B462 Gr. N10276 ... | E575 Gr. N 10275(1), (2) | |||||

60Ni 22Cr9Mo 3,5Cb | B564GR N 06625 ... | B443 Gr. N06625 (3), (5) | |||||

42Ni 21,5Cr 3Mo 2,3Cu | B564 Gr N08825 | B424Gr. N08825 (3),(7) | |||||

Betriebsdrücke nach Klassen, psig | |||||||

Temp., F | 150 | 100 | 400 | 600 | 900 | 1500 | 2500 |

20 bis 100 | 290 | 750 | 1000 | 1500 | 2250 | 3750 | 6250 |

200 | 260 | 750 | 1000 | 1500 | 2250 | 3750 | 5250 |

300 | 230 | 730 | 970 | 1455 | 2185 | 3640 | 5070 |

400 | 200 | 700 | 330 | 1395 | 2035 | 3490 | 5820 |

500 | 170 | 665 | 885 | 1330 | 1995 | 3325 | 5540 |

600 | 140 | 605 | 805 | 1210 | 1815 | 3025 | 5040 |

550 | 125 | 590 | 785 | 1175 | 1755 | 2940 | 4905 |

700 | 110 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

750 | 95 | 530 | 710 | 1065 | 1535 | 2660 | 4430 |

800 | 80 | 510 | 675 | 1015 | 1525 | 2540 | 4230 |

850 | 65 | 485 | 650 | 975 | 1460 | 2435 | 4060 |

900 | 50 | 450 | 500 | 900 | 1350 | 2245 | 3745 |

950 | 35 | 385 | 515 | 775 | 1150 | 1930 | 3220 |

1000 | 20 | 365 | 485 | 725 | 1090 | 1820 | 3030 |

1050 | 360 | 480 | 720 | 1080 | 1800 | 3000 | |

1100 | 325 | 430 | 645 | 965 | 1610 | 2685 | |

1150 | 275 | 365 | 550 | 825 | 1370 | 2285 | |

1200 | 205 | 275 | 410 | 615 | 1030 | 1715 | |

1250 | 165 | 220 | 330 | 495 | 825 | 1370 | |

1300 | 120 | 150 | 240 | 360 | 500 | 1000 | |

Hastelloy-Korrosionsdaten